Wire wound resistors are a type of electronic component that is used to limit or control the flow of electric current in a circuit. They are commonly used in a wide range of electronic devices and equipment, including power supplies, amplifiers, and industrial machinery. In order to ensure the quality and performance of wire wound resistors, there are certain product standards that must be met.One of the most important product standards for wire wound resistors is the resistance value. The resistance value of a resistor is a measure of how much it resists the flow of electric current. This value is typically measured in ohms, and wire wound resistors are available in a wide range of resistance values to suit different applications. It is important for wire wound resistors to have a consistent and accurate resistance value in order to ensure that they function properly in a circuit.Another important product standard for wire wound resistors is the power rating. The power rating of a resistor is a measure of how much power it can safely dissipate without overheating. Wire wound resistors are available in a range of power ratings, and it is important to select a resistor with a power rating that is appropriate for the application in which it will be used. Using a resistor with a power rating that is too low can result in overheating and damage to the resistor, while using a resistor with a power rating that is too high can result in reduced performance and reliability.In addition to resistance value and power rating, there are several other product standards that are important for wire wound resistors. These include temperature coefficient, tolerance, and voltage rating. The temperature coefficient of a resistor is a measure of how its resistance value changes with temperature. Wire wound resistors are available with different temperature coefficients, and it is important to select a resistor with a temperature coefficient that is appropriate for the temperature range in which it will be used.The tolerance of a resistor is a measure of how closely its actual resistance value matches its specified resistance value. Wire wound resistors are available with different tolerance values, and it is important to select a resistor with a tolerance that is appropriate for the application in which it will be used. Using a resistor with a tolerance that is too high can result in inaccuracies in the circuit, while using a resistor with a tolerance that is too low can result in reduced performance and reliability.Finally, the voltage rating of a resistor is a measure of the maximum voltage that it can safely withstand. Wire wound resistors are available with different voltage ratings, and it is important to select a resistor with a voltage rating that is appropriate for the voltage levels in the circuit in which it will be used. Using a resistor with a voltage rating that is too low can result in damage to the resistor and the circuit, while using a resistor with a voltage rating that is too high can result in reduced performance and reliability.In conclusion, wire wound resistors are an important electronic component that is used in a wide range of applications. In order to ensure the quality and performance of wire wound resistors, it is important to adhere to certain product standards, including resistance value, power rating, temperature coefficient, tolerance, and voltage rating. By selecting wire wound resistors that meet these standards, you can ensure that your electronic devices and equipment operate safely and reliably.

The stainless steel resistor scenario involves several industries that play a crucial role in the production and utilization of this important component. Stainless steel resistors are widely used in various applications across different sectors, making them an essential part of modern technology and manufacturing processes. In this article, we will explore the industries involved in the stainless steel resistor scenario and how they contribute to its production and use.1. Electronics Industry:

The electronics industry is one of the primary sectors that heavily rely on stainless steel resistors for various applications. Stainless steel resistors are commonly used in electronic devices such as computers, smartphones, televisions, and other consumer electronics. These resistors help regulate the flow of electricity within these devices, ensuring proper functioning and preventing damage from electrical surges. The electronics industry is a major consumer of stainless steel resistors, driving demand for high-quality and reliable components.2. Automotive Industry:

The automotive industry is another key player in the stainless steel resistor scenario. Stainless steel resistors are used in vehicles for a wide range of applications, including engine control systems, lighting systems, and climate control systems. These resistors help regulate the flow of electricity in various components, ensuring optimal performance and efficiency. The automotive industry relies on stainless steel resistors to enhance the safety, reliability, and functionality of vehicles, making them an essential component in modern automotive technology.3. Industrial Manufacturing:

The industrial manufacturing sector is a significant user of stainless steel resistors for various applications. Stainless steel resistors are used in industrial equipment and machinery to regulate electrical currents, control temperature, and ensure proper functioning of critical systems. Industries such as aerospace, defense, energy, and telecommunications rely on stainless steel resistors to maintain operational efficiency and safety in their manufacturing processes. The industrial manufacturing sector plays a crucial role in driving demand for stainless steel resistors and promoting innovation in their design and production.4. Renewable Energy:

The renewable energy sector is a growing market for stainless steel resistors, particularly in solar and wind power generation systems. Stainless steel resistors are used in inverters, charge controllers, and other components of renewable energy systems to regulate electricity flow and ensure efficient energy conversion. The renewable energy industry is driving demand for high-performance and durable stainless steel resistors that can withstand harsh environmental conditions and provide reliable operation in renewable energy applications.5. Medical Devices:

The medical devices industry is another important sector that utilizes stainless steel resistors for various applications. Stainless steel resistors are used in medical equipment such as diagnostic devices, imaging systems, and surgical instruments to regulate electrical currents and ensure accurate and reliable performance. The medical devices industry relies on stainless steel resistors to meet stringent quality and safety standards, making them an essential component in the design and production of medical devices.In conclusion, the stainless steel resistor scenario involves a diverse range of industries that rely on this important component for various applications. From electronics and automotive to industrial manufacturing, renewable energy, and medical devices, stainless steel resistors play a crucial role in modern technology and manufacturing processes. These industries drive demand for high-quality and reliable stainless steel resistors, promoting innovation and advancement in their design and production. As technology continues to evolve, the demand for stainless steel resistors is expected to grow, further expanding their role in shaping the future of various industries.

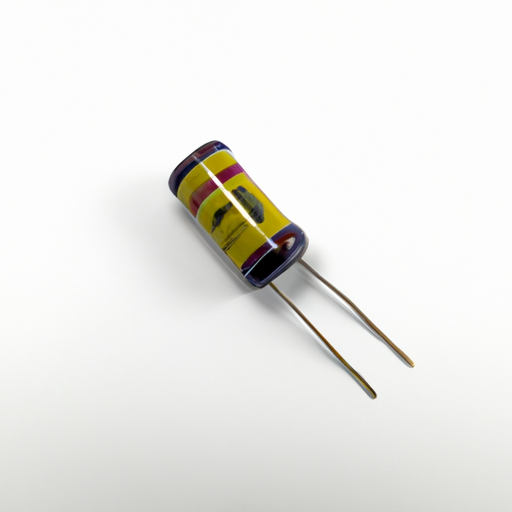

A capacitor is an essential component in many electronic devices, serving as a temporary energy storage device that can release its stored energy quickly when needed. Capacitors are used in a wide range of applications, from power supplies and audio equipment to computers and telecommunications devices. They come in various shapes and sizes, with different capacitance values and voltage ratings to suit different needs.When it comes to purchasing a capacitor, the price can vary depending on several factors. In this article, we will explore the different types of capacitors, their uses, and how much you can expect to pay for them.Types of CapacitorsThere are several types of capacitors available on the market, each with its own unique characteristics and applications. Some of the most common types of capacitors include:1. Ceramic Capacitors: These capacitors are made of ceramic materials and are widely used in electronic circuits due to their small size, high capacitance values, and low cost. Ceramic capacitors are suitable for high-frequency applications and are available in both surface mount and through-hole configurations.2. Electrolytic Capacitors: Electrolytic capacitors are polarized capacitors that use an electrolyte as the dielectric material. They have a higher capacitance value compared to ceramic capacitors and are commonly used in power supply circuits and audio equipment. Electrolytic capacitors are available in both aluminum and tantalum constructions.3. Film Capacitors: Film capacitors are made of a thin plastic film as the dielectric material and are known for their high stability and reliability. They are used in a wide range of applications, including filtering, coupling, and timing circuits. Film capacitors are available in various types, such as polyester, polypropylene, and polycarbonate.4. Tantalum Capacitors: Tantalum capacitors are polarized capacitors that use tantalum as the dielectric material. They have a high capacitance value and are known for their low leakage current and high reliability. Tantalum capacitors are commonly used in portable electronic devices, such as smartphones and laptops.5. Supercapacitors: Supercapacitors, also known as ultracapacitors, are a type of capacitor that can store a large amount of energy and release it quickly. They are used in applications that require high power density and fast charging and discharging cycles, such as hybrid vehicles and renewable energy systems.Cost of CapacitorsThe cost of a capacitor can vary depending on several factors, including the type of capacitor, capacitance value, voltage rating, and brand. In general, ceramic capacitors are the most affordable option, with prices ranging from a few cents to a few dollars, depending on the capacitance value and voltage rating.Electrolytic capacitors are slightly more expensive than ceramic capacitors, with prices typically ranging from a few cents to several dollars, depending on the capacitance value, voltage rating, and construction material (aluminum or tantalum).Film capacitors are also relatively affordable, with prices ranging from a few cents to a few dollars, depending on the capacitance value, voltage rating, and type of film material (polyester, polypropylene, or polycarbonate).Tantalum capacitors are the most expensive type of capacitor, with prices ranging from a few cents to several dollars, depending on the capacitance value, voltage rating, and brand. Tantalum capacitors are known for their high reliability and low leakage current, making them a popular choice for critical applications.Supercapacitors are the most expensive type of capacitor, with prices ranging from a few dollars to several hundred dollars, depending on the capacitance value, voltage rating, and brand. Supercapacitors are used in high-power applications that require fast charging and discharging cycles, making them a valuable investment for certain industries.Factors Affecting Capacitor PricesSeveral factors can affect the price of a capacitor, including:1. Capacitance Value: The capacitance value of a capacitor is a measure of its ability to store charge. Capacitors with higher capacitance values are generally more expensive than those with lower capacitance values, as they can store more energy.2. Voltage Rating: The voltage rating of a capacitor indicates the maximum voltage that the capacitor can withstand without breaking down. Capacitors with higher voltage ratings are typically more expensive than those with lower voltage ratings, as they are designed to handle higher voltages.3. Construction Material: The construction material of a capacitor can also affect its price. Capacitors made of high-quality materials, such as tantalum or polypropylene, are generally more expensive than those made of lower-quality materials, such as aluminum or polyester.4. Brand: The brand of a capacitor can also impact its price. Capacitors from well-known brands with a reputation for quality and reliability are typically more expensive than generic or lesser-known brands.5. Packaging: The packaging of a capacitor can also affect its price. Surface mount capacitors are generally more expensive than through-hole capacitors, as they require specialized equipment for installation.ConclusionIn conclusion, the price of a capacitor can vary depending on several factors, including the type of capacitor, capacitance value, voltage rating, construction material, brand, and packaging. While ceramic capacitors are the most affordable option, tantalum capacitors are the most expensive due to their high reliability and low leakage current. Supercapacitors are also a costly investment, but they offer high power density and fast charging and discharging cycles for specific applications.When purchasing a capacitor, it is essential to consider your specific needs and requirements to choose the right type of capacitor for your application. By understanding the different types of capacitors and the factors that affect their prices, you can make an informed decision and ensure that you get the best value for your money.

Capacitors are essential components in electronic circuits, used to store and release electrical energy. They come in various shapes and sizes, each designed for specific applications. In this article, we will discuss some of the most popular capacitor models commonly used in electronic devices.1. Ceramic Capacitors:

Ceramic capacitors are one of the most widely used types of capacitors due to their small size, high reliability, and low cost. They are made of ceramic materials with a thin layer of metal on each side, acting as the electrodes. Ceramic capacitors are available in different types, such as multilayer ceramic capacitors (MLCCs) and ceramic disc capacitors. They are commonly used in filtering, decoupling, and timing applications in electronic circuits.2. Electrolytic Capacitors:

Electrolytic capacitors are polarized capacitors that use an electrolyte as the dielectric material. They are available in two main types: aluminum electrolytic capacitors and tantalum electrolytic capacitors. Aluminum electrolytic capacitors have a higher capacitance value and are commonly used in power supply circuits. Tantalum electrolytic capacitors have a smaller size and higher reliability, making them suitable for compact electronic devices.3. Film Capacitors:

Film capacitors are non-polarized capacitors that use a thin film as the dielectric material. They are available in various types, such as polyester film capacitors, polypropylene film capacitors, and metalized film capacitors. Film capacitors have high stability, low leakage current, and high temperature tolerance, making them suitable for high-frequency and high-voltage applications.4. Tantalum Capacitors:

Tantalum capacitors are polarized capacitors that use tantalum as the dielectric material. They have a high capacitance value and low equivalent series resistance (ESR), making them suitable for filtering and decoupling applications in electronic circuits. Tantalum capacitors are available in surface mount and through-hole configurations, with the surface mount type being more commonly used in modern electronic devices.5. Supercapacitors:

Supercapacitors, also known as ultracapacitors or double-layer capacitors, are a type of capacitor that can store a large amount of energy compared to traditional capacitors. They have a high capacitance value and low equivalent series resistance (ESR), allowing them to deliver high power in short bursts. Supercapacitors are commonly used in applications that require rapid energy storage and release, such as hybrid vehicles, renewable energy systems, and portable electronics.6. Variable Capacitors:

Variable capacitors, also known as tuning capacitors or trimmer capacitors, are capacitors with adjustable capacitance values. They are commonly used in radio frequency (RF) circuits, antennas, and tuning circuits to adjust the frequency response of the circuit. Variable capacitors are available in different types, such as air variable capacitors, ceramic trimmer capacitors, and vacuum variable capacitors.7. Mica Capacitors:

Mica capacitors are capacitors that use mica as the dielectric material. They have high stability, low loss, and high insulation resistance, making them suitable for high-frequency and high-temperature applications. Mica capacitors are commonly used in radio frequency (RF) circuits, audio equipment, and precision instrumentation.In conclusion, capacitors are essential components in electronic circuits, used for storing and releasing electrical energy. There are various types of capacitors available, each designed for specific applications based on their capacitance value, voltage rating, size, and other characteristics. The popular capacitor models discussed in this article are commonly used in electronic devices and circuits, providing reliable performance and functionality.